30+

Industry experience

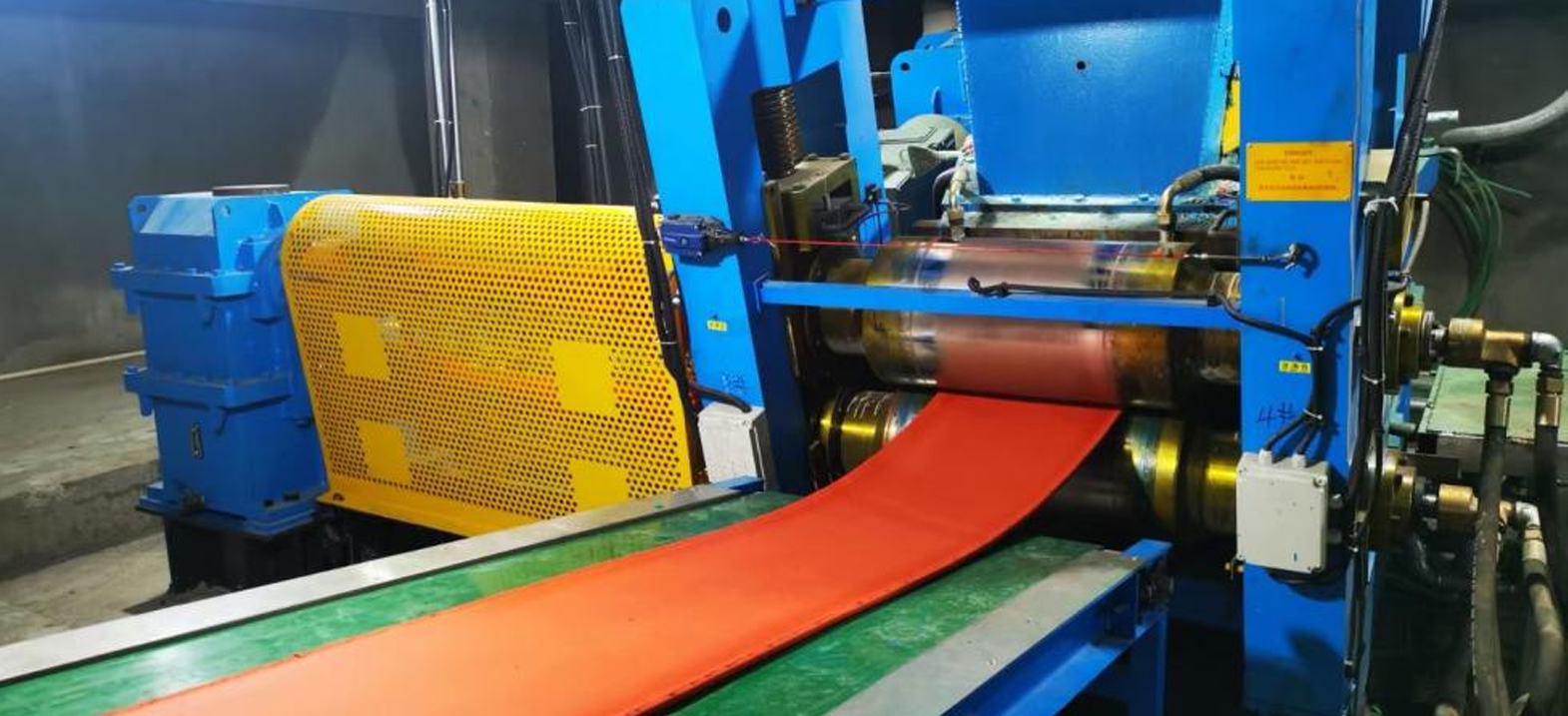

FieldsMaster is your partnering in sport fields solutions, providing you with globally leading field solutions. We adhere to the concept of sustainable development, continuously improving production processes, and enhancing environmental equipment over our two decades of experience. In 2020, FieldsMaster took a significant step towards sustainability by adopting the continuous high-temperature drying and vulcanization process, replacing traditional sulfur tanks, effectively reducing sulfur emissions. We pay attention to every detail, ensuring that customer needs are met. Choosing FieldsMaster means choosing a reliable partner to collaboratively create green, efficient, and outstanding sports facilities.

Industry experience

Annual output

Automated factory

Production base

Rubber internal mixers

Testing instruments and equipment

countries and regions

Certificate of Utility Model Patent