Introduction to ETPU Granules: A New Option for Playground Sub-Base Systems

Product Background & Application

The ETPU granules we supply are sourced from BASF Infinergy (non-prime grade) and are not produced in-house. After careful selection and performance evaluation, we apply them as sub-base material for children’s playgrounds. While this grade is not intended for high-performance shoe soles, it has proven to be highly stable and cost-effective in outdoor ground installations.

Thanks to its competitive price and solid performance, market demand continues to grow. Our monthly supply capacity reaches around 8 tons, and it’s still not enough to meet the full demand.

Key Features

High Temperature Resistance: With a tolerance up to 150°C, ETPU won’t deform, collapse, or hydrolyze under typical conditions.

Stable & Safe: Designed for soft fall surfaces, it provides stable performance and a comfortable surface when combined with PU binders.

Flexible Sizing & Aesthetic Options: Various colors and grain sizes are available to match different site designs and safety needs.

Common Sizes & Application Suggestions

2-4mm: Ideal for 8-12mm base layer thickness

4-6mm: Most common size, suitable for 10-20mm thickness

5-8mm: Typically used in 40mm surfaces under school equipment zones

The coarser the granule, the easier it is to trowel and spread. For standard playground designs, 20mm ETPU sub-base + 10mm EPDM top layer is often used internationally.

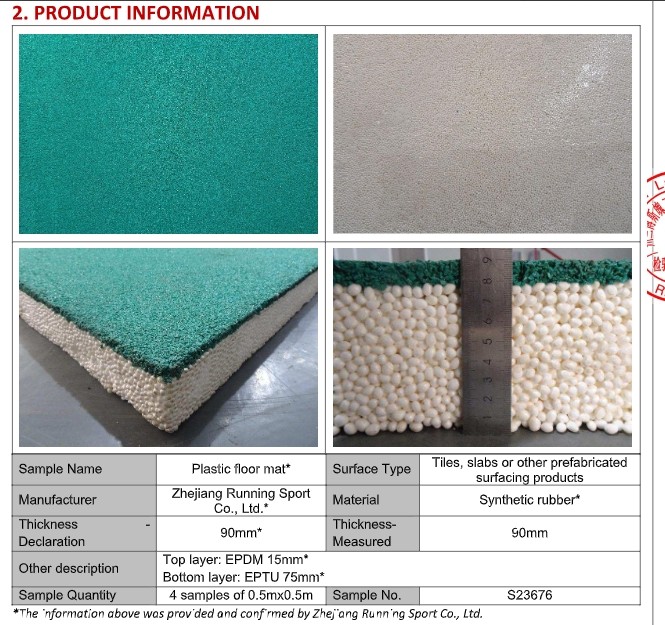

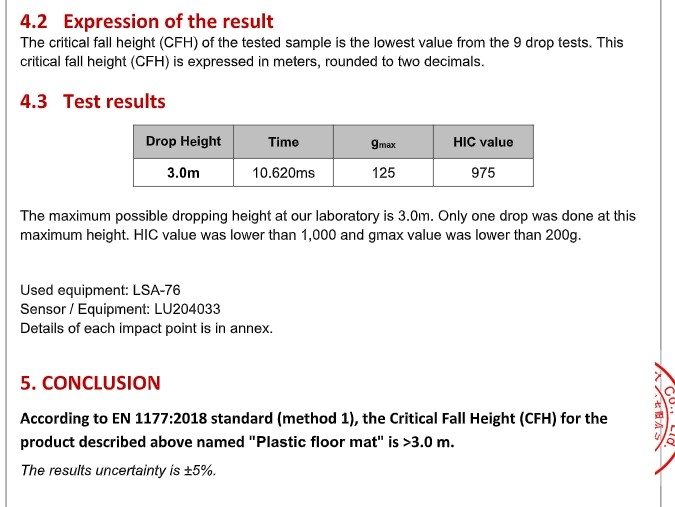

New System Structure (Complies with HIC Standards)

EPDM 15mm + ETPU 75mm (Total thickness: 90mm)

Meets international HIC shock absorption standards

Application Quantity & Ratio

Recommended quantity: 0.15kg per m² per 1mm thickness

Binder ratio: ETPU : PU = 1 : 4.5

Product Longevity

Based on BASF Infinergy ETPU data and usage in real-world projects, even as non-prime grade, this material still demonstrates superior performance:

>55% rebound rate for long-lasting elasticity

Wide temperature tolerance: Performs well from -20°C to above +40°C

High resilience: Excellent anti-fatigue and compressive recovery

When installed correctly and maintained well, the estimated lifespan is 15–20 years, possibly even longer in favorable conditions.

If you’d like, I can also help you export this document as a downloadable file or prepare visuals for your blog post.